Reverse Engineering

Definition:

Reverse engineering is the process of reconstructing the design, geometry, material properties, and functional intent of an existing physical component or system. It is commonly used when design data is missing, legacy parts need reproduction, or improvements are sought in performance and manufacturing.

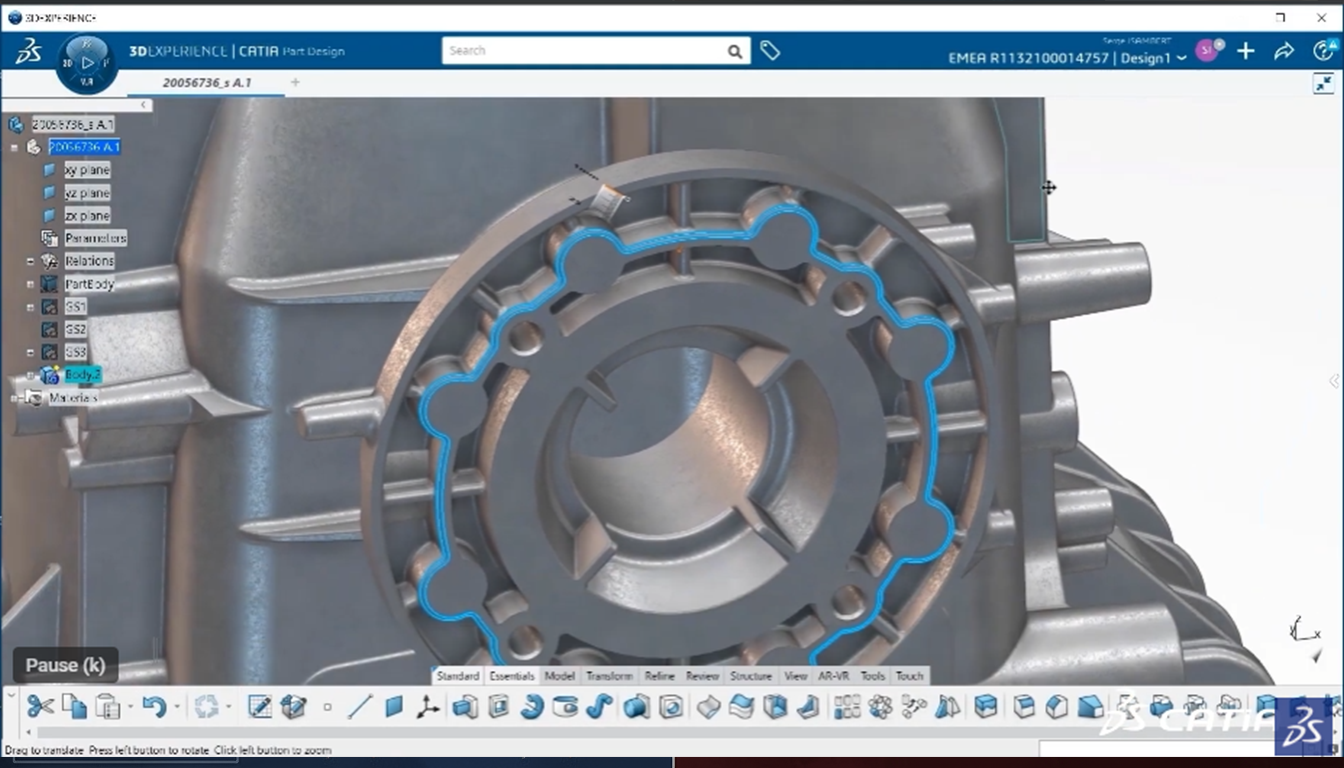

As computer-aided design (CAD) has become more popular, reverse engineering has become a viable method to create a 3D virtual model of an existing physical part for use in 3D CAD, CAM, CAE or other software. The reverse-engineering process involves measuring an object and then reconstructing it as a 3D model. The physical object can be measured using 3D scanning technologies like CMMs, laser scanners, structured light digitizers, or industrial CT scanning (computed tomography).

In CATIA, and by using 3DEXPERIENCE, Reverse Engineering became a very powerful design tool, and our Subject Matter Experts will present you the latest innovations in this cutting edge-domain.

Steps in Reverse Engineering

Data Acquisition

- 3D Scanning / CMM: Collect point cloud or mesh data of the component.

- CT Scans / NDT: Capture internal geometries or defects.

Data Processing

- Cleaning, filtering, and aligning point clouds.

- Mesh optimization and segmentation into features.

CAD Reconstruction

- Surface fitting, parametric feature creation, and solid modeling.

- Conversion into editable CAD geometry (STEP, IGES, CATPart).

Material & Property Analysis

- Chemical composition analysis (spectrometry).

- Mechanical testing (tensile, hardness, microstructure).

Simulation & Validation

- FEA, CFD, and multiphysics simulations to validate performance.

- Tolerance and deviation analysis between original & CAD model.

Re-manufacturing / Additive / Casting

- CAM programming, additive manufacturing, or conventional processes to reproduce the component.

- Integration into the digital twin for lifecycle tracking.

Applications

- Defense & Aerospace: Legacy spare parts, worn-out assemblies, crash/ballistic components.

- Automotive & Railways: Obsolete spares, tooling, sheet metal dies.

- Medical: Patient-specific implants and prosthetics.

- Heritage & Architecture: Documentation of monuments, sculptures, and artifacts.

HOME

HOME