01

Automotive OEMs and Suppliers

CAVA enables manufacturers to fulfill international rules, norms, and standards during the entire design process, from concept to homologation.

CAVA

CAVA

Smart Vehicle Architecture Validation within CATIA.

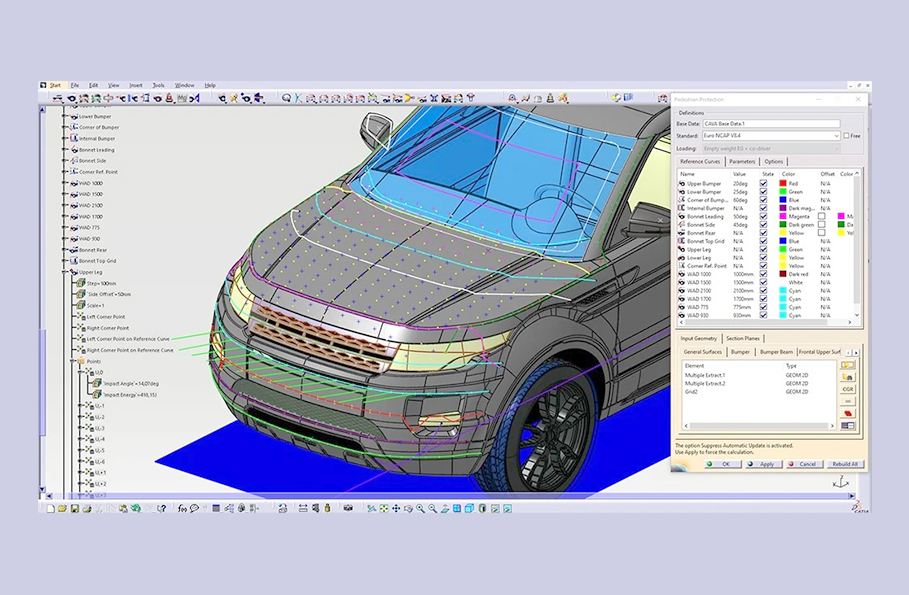

CAVA is a feature-based and associative technology that enables the validation of vehicle designs against various international rules, norms, and standards during the entire design process. Developed in collaboration with German car manufacturers, CAVA integrates these standards as CATIA features, allowing designers to check vehicle geometry for compliance efficiently.

It integrates directly with CATIA V5 and 3DEXPERIENCE platforms.It includes modules like CAVA Vision, CAVA Safety, CAVA Manikin, CAVA Wiper, and more, each focusing on specific compliance aspects.Its core purpose is virtual homologation, helping manufacturers ensure that vehicles meet all legal and safety requirements digitally before building prototypes.

OVA means Overall Vehicle Architecture is Validates the complete vehicle packaging, ensuring components, assemblies, and dimensions meet international regulatory standards. Helps engineers optimize space and layout efficiently.

Assesses driver visibility and sightlines, reducing blind spots and ensuring compliance with global safety standards. Enhances overall driver and pedestrian safety.

Evaluates safety-critical areas such as pedestrian protection zones, head-impact regions, and crash compliance. Helps minimize risks during the design stage.

CAVA Tools Provides smart utilities to automate compliance checks, validate designs, and generate reports efficiently. Complements other CAVA modules for a complete virtual vehicle validation workflow.

CAVA for V6 by TECHNIA GmbH is a specialized solution that focuses on validating vehicle designs against global safety and regulatory requirements. Built to support the automotive industry, it integrates smoothly with CATIA V6 and the 3DEXPERIENCE platform, giving design teams the ability to check compliance directly within their existing workflows.

By using CAVA for V6, manufacturers and suppliers can identify compliance issues early, reduce reliance on physical prototypes, and speed up the approval process. This not only helps in meeting national and international standards with confidence but also improves efficiency, reduces costs, and shortens time-to-market.

Benefits of CAVA

Intelligent solutions driving global industries.

Intelligent solutions driving global industries.

CAVA enables manufacturers to fulfill international rules, norms, and standards during the entire design process, from concept to homologation.

While primarily focused on automotive applications, the principles of CAVA can be applied to aircraft design to ensure compliance with relevant standards.