01

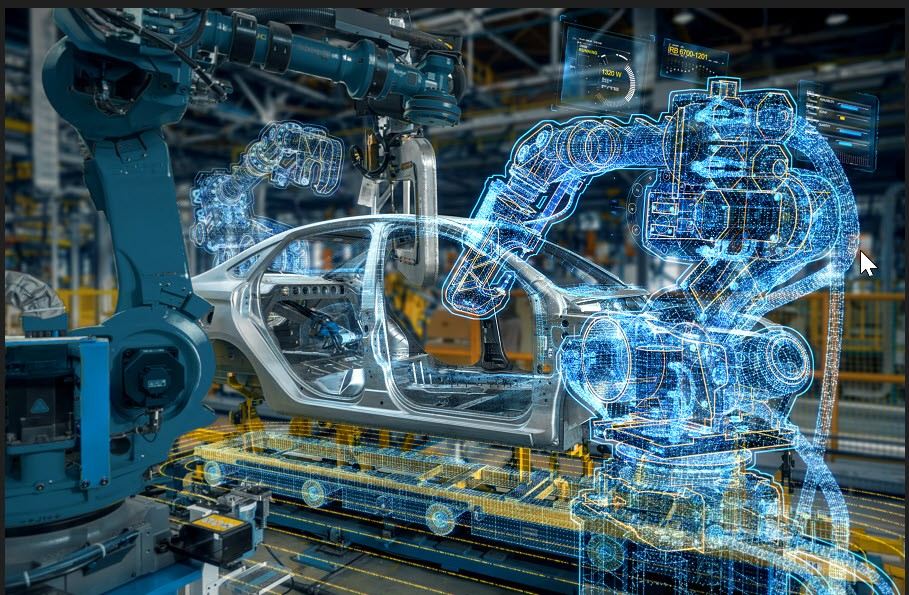

Automotive & Aerospace

Accelerate design-to-production cycles, improve quality through virtual simulations, and reduce costs by optimizing robotics and assembly lines before implementation.

DELMIA

DELMIA

Unifying design, simulation, and execution for smarter, sustainable manufacturing.

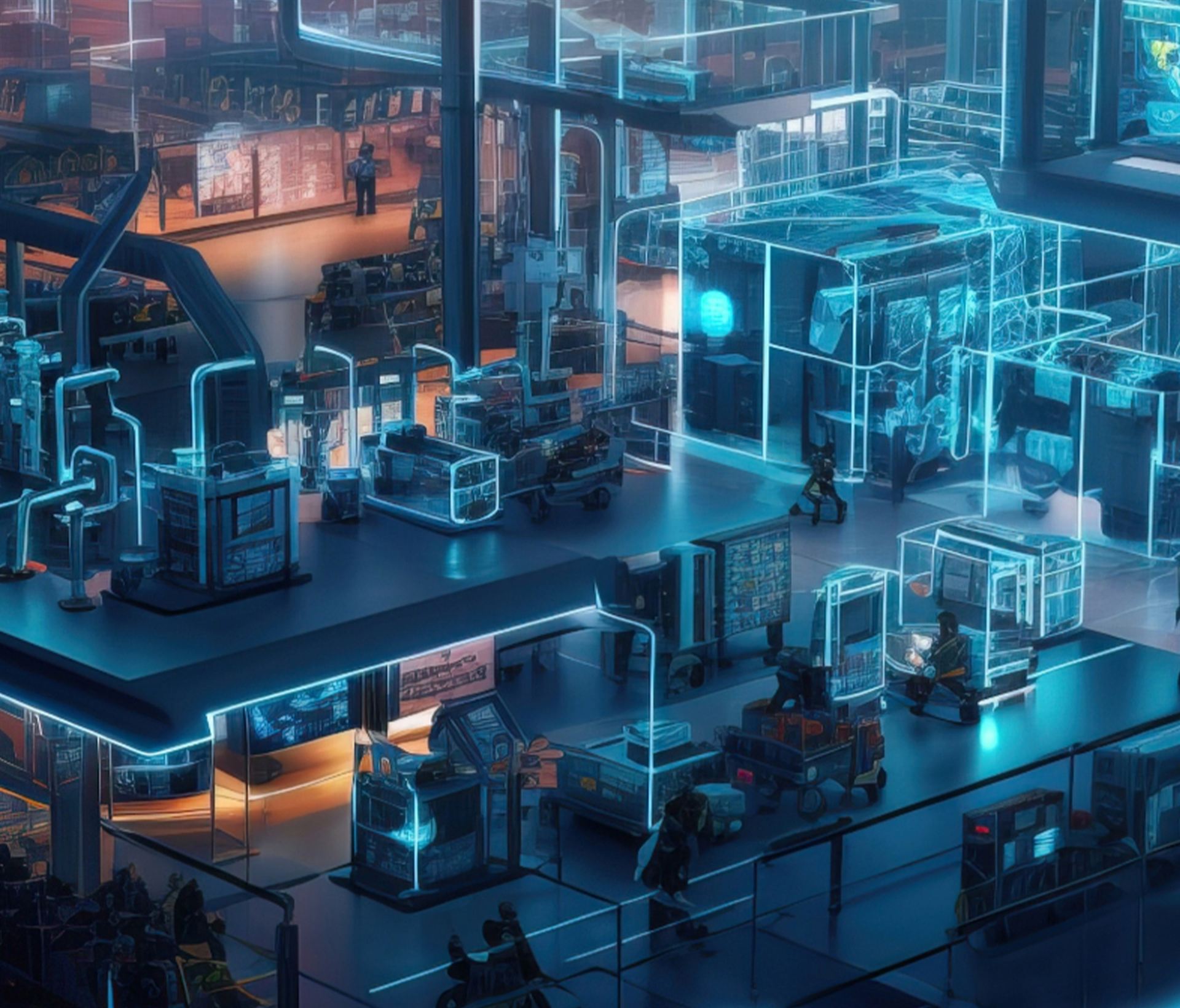

DELMIA (Digital Enterprise Lean Manufacturing Interactive Application) is Dassault Systèmes’ powerful digital manufacturing and operations platform that bridges the gap between the virtual and real worlds. It empowers organizations to design, simulate, and optimize manufacturing systems, robotics, and supply chains within a single connected environment. By creating virtual twins of factories, processes, and logistics, DELMIA helps businesses identify challenges early, reduce risks, and accelerate innovation before physical implementation.

DELMIA builds a digital twin of factories, processes, and supply chains, enabling companies to simulate production workflows before they go live. This reduces errors, minimizes downtime, and ensures efficient resource utilization.

With powerful 3D tools, engineers can design, program, and validate robotic and manual operations in a virtual environment. This ensures safer, faster, and more accurate shop-floor execution with less physical trial and error.

DELMIA connects production processes through real-time monitoring, quality tracking, and compliance management. By integrating people, machines, and data, it ensures end-to-end visibility and smarter decision-making on the shop floor.

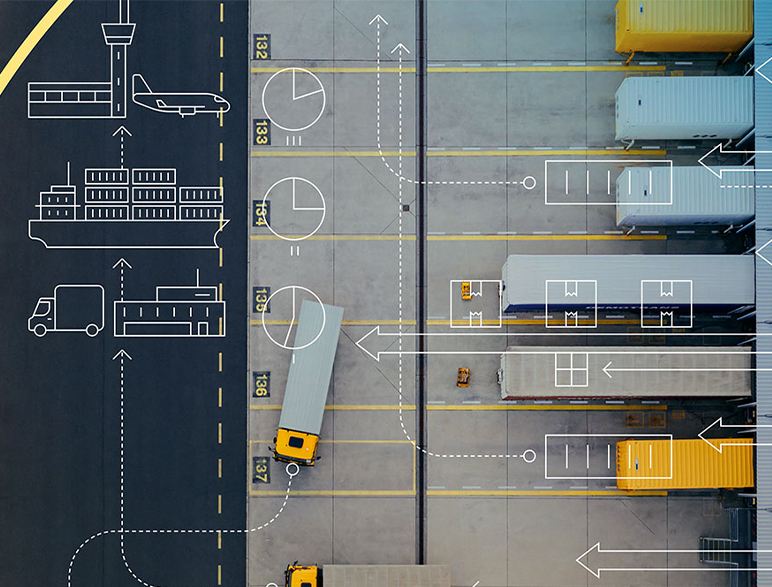

Using intelligent planning tools, DELMIA optimizes scheduling, logistics, and resource allocation. It helps manufacturers adapt quickly to changing demands, reduce lead times, and maintain resilience in global supply chains.

One of DELMIA’s core strengths is its Virtual Twin Experience, which creates a digital replica of manufacturing systems. Companies can simulate production, logistics, ergonomics, and maintenance in advance—identifying bottlenecks and risks before they occur. This not only drives operational excellence but also helps achieve sustainability goals, as processes can be optimized to minimize energy usage and environmental impact.

Smart Technologies Driving Industrial Innovation.

Smart Technologies Driving Industrial Innovation.

Accelerate design-to-production cycles, improve quality through virtual simulations, and reduce costs by optimizing robotics and assembly lines before implementation.

Enhance efficiency by digitally validating production processes, minimizing downtime, and ensuring precision in complex machinery manufacturing.

Support compliance with strict regulatory standards, improve production planning, and optimize supply chains to ensure timely delivery of life-saving products.

Respond faster to changing consumer demands with agile manufacturing, efficient resource utilization, and sustainable production practices.

Improve collaboration across stakeholders, simulate complex building processes, and ensure projects are delivered on time with reduced rework and waste.

Empowering Smarter Manufacturing.

Empowering Smarter Manufacturing.

By simulating factories and processes virtually, DELMIA helps reduce errors, minimize downtime, and streamline operations for faster delivery.

Virtual validation of production and supply chains cuts down on physical prototypes, prevents costly rework, and reduces operational risks.

With the 3DEXPERIENCE platform, teams across engineering, planning, and production work on a single source of truth—improving alignment and smarter decision-making.

DELMIA enables resource optimization, waste reduction, and energy - efficient manufacturing, helping businesses stay sustainable while gaining a market edge.